Then come to the experts

In today’s fast-paced and competitive market, it is essential for businesses to constantly seek innovative solutions to enhance efficiency, productivity, and sustainability. At SHS Group (Smart Hydraulic System), we specialize in providing cutting-edge technology that transforms traditional hydraulic systems into intelligent, high-performing assets for a wide range of equipment and heavy machinery applications.Our unique solution is the integration of a smart hydraulic pump drive system into all power transmission components, from hydraulic pumps to valves. This advanced technology enables real-time information sharing among all system components, optimizing performance, and minimizing energy losses.

At SHS Group (Smart Hydraulic System), we are dedicated to helping businesses like yours maximize efficiency, productivity, and sustainability through our cutting-edge hydraulic system solutions. Our innovative technology can transform your existing equipment and heavy machinery into high-performing assets, significantly improving overall performance and reducing environmental impact.

The most comprehensive complete system warranty in the solar industry.

The most comprehensive complete system warranty in the solar industry.

The most comprehensive complete system warranty in the solar industry.

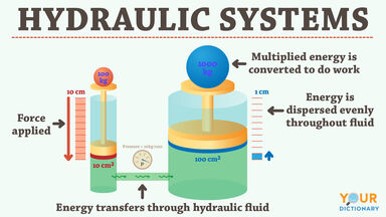

Fluid – oil that moves throughout the system (typically petroleum)

Accumulator – stores energy with pressurized gas

Reservoir/receiver – holds excess fluid

Fluid filter – removes contaminants from fluid

Pump/compressor – pumps the fluid through the system (can be manual or electric)

Pistons – create different pressure zones throughout the system

Motor – power source for the pump

Control valves – controls the direction and flow rate of the fluid

Piping/tubing – allows the pressurized fluid to travel from one place to another

Actuator/cylinder – receives the fluid and converts the energy to do work

We provide the best quality in the shortest possible time

Payments will be made in cash to your account

We buy all types of waste such as copper, aluminum, steel, batteries, coated wire and more... at the best price

You will leave us satisfied. Our prices are unique

Pumping applications represent a significant opportunity for applying variable speed drives (SHS®) in new as well as retrofit installations. The majority of pumping applications need to be controlled. It is unlikely that a pump will run continuously at a maximum speed.

Variable speed drives are crucial when limiting the life cycle costs (LCC) of a pump station. The three main costs are energy, initial investment and maintenance.

Many analyses show that energy consumption is the dominating element of the LCC, especially if pumps run more than 2,000 hours per year. The investment cost of the equipment needed (variable speed drives, motors and pumps) is relatively low when compared to the total LCC.

Maintenance is the third main cost component. Active control using a SHS® works as a means of preventive maintenance, limiting maintenance costs in many ways.

SHS® control has several benefits in pumping systems. The most important is energy saving. Accurate control of the pump system is another benefit. With SHS® running the pump system, linking to other automation systems is easy by means of common fieldbus gateways.

Many people get the terms hydraulic system and pneumatic system mixed up. It’s easy to understand since they both use fluid power to perform work. They also share many components, such as pumps and valves. However, there is one key difference:

You’re more likely to see hydraulic systems in large types of machinery because they are capable of lifting heavier loads. Pneumatic systems are better for smaller machines, such as air compressors or dental drills. They are also cleaner than hydraulic systems because they don’t leak oil.

Design and development: nonegar Pardazesh

All rights of this website are reserved for Smart Hydraulic Systems